1 Minute to understand

Ten business scenarios for mold full life cycle management

Business difficulties

Business process breakpoint

No professional mold management system, multi-system data is not connected, information fragmentation;

Mold resume missing

Mold basic information and the use of the situation without platform control, information scattered, miscellaneous;

Asset control risk

The cost management is not clear, the asset ownership is not clear, the asset inventory efficiency is low, and the mold life is not supervised;

Production guarantee risk

Production capacity is not clear, mold opening lag; overdue maintenance, mold damage delay production;

Ways of resolution

The mold assets are clear

The system accurately manages each set of mold information, and all mold assets can be checked;

The mold resume is perfect

The system accurately manages each set of mold information, and all mold assets can be checked;

Mold forecast maintenance

Reduce the mold fault, prolong the mold life, reduce the maintenance cost;

Mold cost control

Mold sharing management, improve the utilization rate of mold, reduce non-essential copy mold opening, reduce the cost of mold;

Core advantage

Full business process

Demand stage: project management, mold bidding, order management, supplier management, settlement management mold opening stage: mold opening instruction, copy mold, mold changing, mold opening progress, mold acceptance asset management: ledger, resume, inventory, allocation, maintenance and scrap

The IoT technology is strong

Leading sensing technology, real-time and accurate collection of mold data mold accurate positioning, automatic inventory, eliminate illegal mold outsourcing mold production capacity, real-time and accurate production beat, production capacity guarantee

Excellent cost control

Mold cost evaluation, provide procurement negotiation basis, effectively control the mold opening cost mold maintenance, life monitoring, reduce the product delivery time and quality risk, reduce the delivery cost of mold sharing management, effectively use the mold, reduce the non-essential mold opening cost

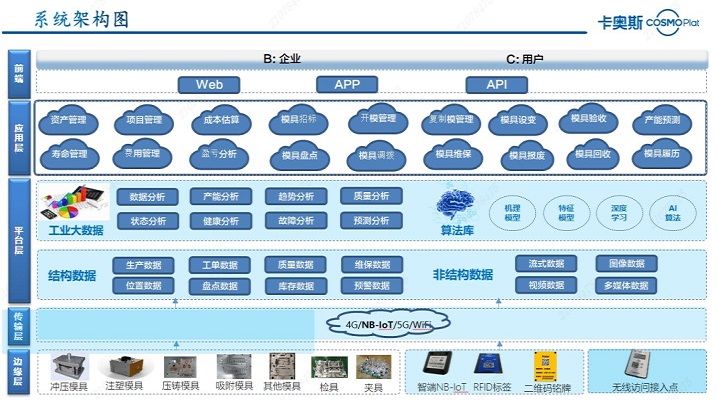

Architecture description

Five-layer architecture layout

Solution Panorama

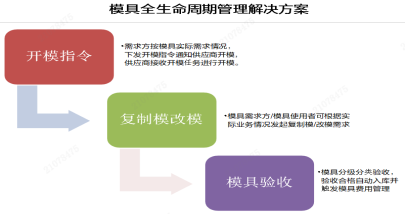

① Mold requirement generation for project approval- ② mold cost evaluation- ③ initiated mold bidding

④ The mold demander initiates the mold opening instruction to the supplier, ⑤ initiates the mold copying and mold repair action based on the actual demand, ⑥ initiates the mold opening progress management and conducts the mold acceptance after the mold opening is completed

⑦ Analyze the production capacity demand, provide the copy mold basis, ⑧ life management, ensure the mold use status, ⑨ predictive maintenance, mold maintenance closed loop

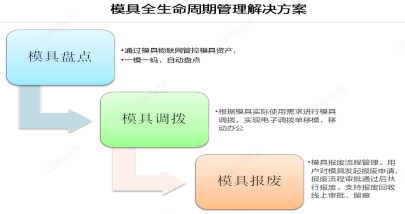

⑩ Manual scanning code inventory, automatic inventory of mold link, mold allocation between ⑪ mold users, ⑫ mold scrap management and mold recovery after scrap

⑬ Record record of each link ⑭ mold management mobile terminal business