Platform Introduction

What can an intelligent equipment management solution do?

Industry pain points

Facility Management Chaos

Facility Management's various maintenance systems and processes rely entirely on manual recording, which is prone to omissions and management losses. Secondly, traditional management models such as manual maintenance records, paper forms, and signature approval have low efficiency and chaotic management.

High equipment failure rate

The equipment has a high failure rate, long maintenance time, and the maintenance mode is post repair. There are many cases of excessive or insufficient maintenance; Enterprises do not have professional knowledge such as equipment maintenance techniques, fault libraries, and fault plans to guide equipment management work in reverse.

Low equipment performance

The production equipment is becoming increasingly mechanized and complex, and the dependence of the production process on equipment is increasing. Equipment failures and shutdowns, as well as the lack of sources for determining effective operating time and performance indicators, result in low equipment performance.

Facility Management Chaos

Facility Management's various maintenance systems and processes rely entirely on manual recording, which is prone to omissions and management losses. Secondly, traditional management models such as manual maintenance records, paper forms, and signature approval have low efficiency and chaotic management.

Service industry

1

General equipment manufacturing industry

2

Specialized equipment manufacturing industry

3

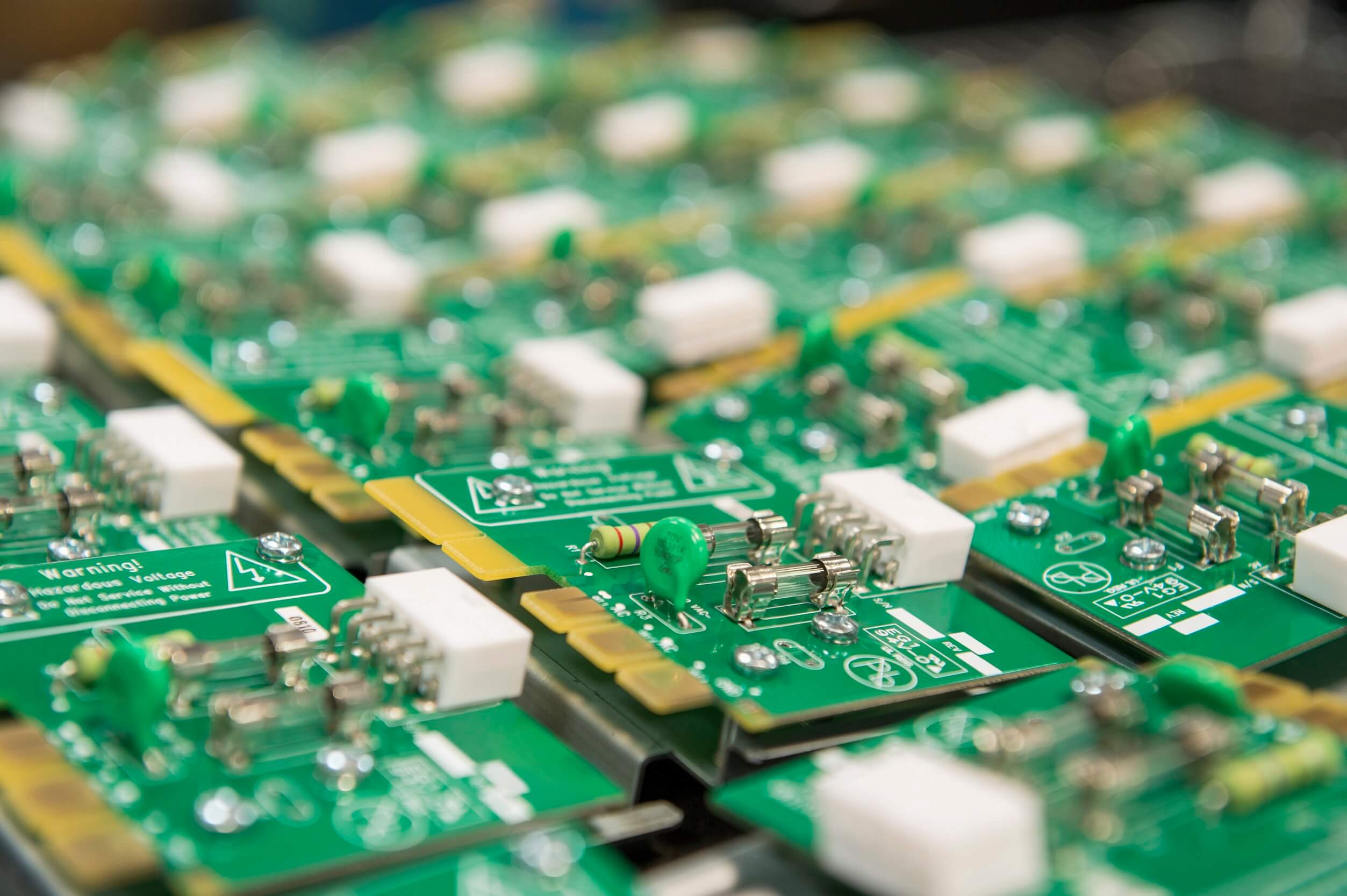

Electrical machinery and equipment manufacturing industry

4

Electronic information manufacturing industry

5

Light industrial manufacturing industry

6

Automotive parts manufacturing industry

Application scenarios

Equipment monitoring

Real time monitoring of equipment parameter changes, upon reaching the set threshold, triggering the broadcast warning to generate an electronic maintenance work order and automatically reporting for repair.

Energy consumption management

Real time monitoring and statistics of energy parameters such as electricity and gas consumption of equipment, monitoring energy consumption, and rational planning of energy consumption.

Equipment maintenance

Support IoT based fault alarm and automatic repair, and support the activation of maintenance worker enthusiasm in the business of rush order mode.

Asset management

Provide a complete equipment usage record to achieve full lifecycle management of assets through equipment procurement, acceptance, maintenance, repair, allocation, and scrapping.

Performance management

Based on IoT data, achieve multi-dimensional performance analysis of production, equipment, and other aspects, providing auxiliary decision-making basis for managers.

Predictive maintenance

Industrial grade AI+mechanism model dual line empowerment, achieving equipment predictive maintenance, emergency fault alarm, and equipment life prediction.

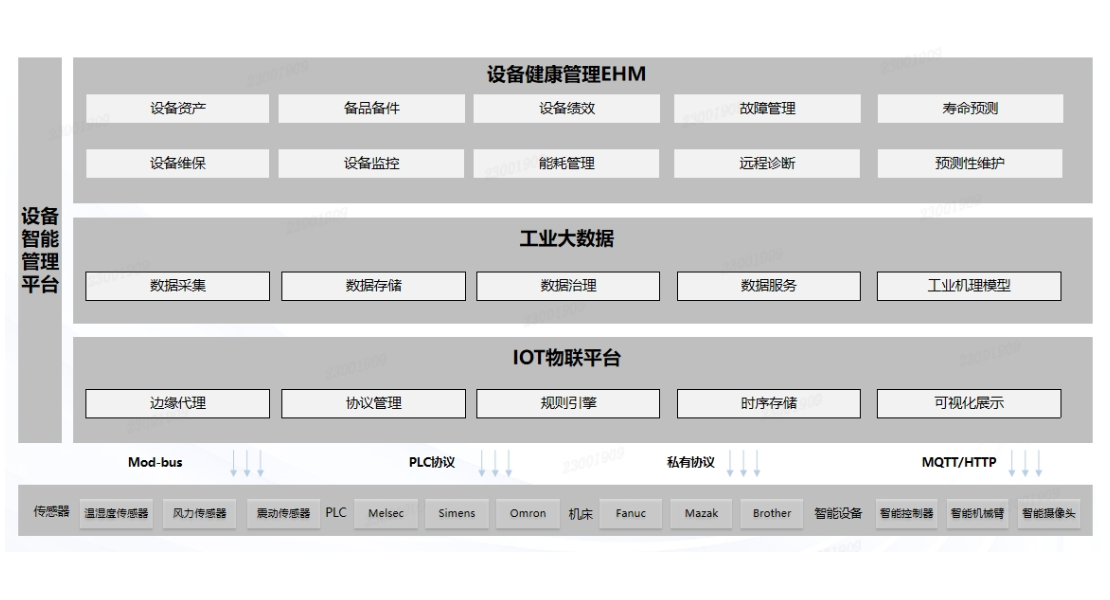

Platform architecture

Equipment intelligent management platform

Advantages of the plan

Strong IoT capabilities

Support for millions of concurrent data; Aggregation device protocol 400+; Accumulate Industrial Model Library 100+

Health control

Full state perception of device status; Real time assessment of device health; Intelligent closed-loop fault warning

Intelligent decision-making optimization

Advance prediction of equipment failures; Accurate diagnosis of equipment failures; Intelligent recommendations for maintenance recommendations

Implementation cases

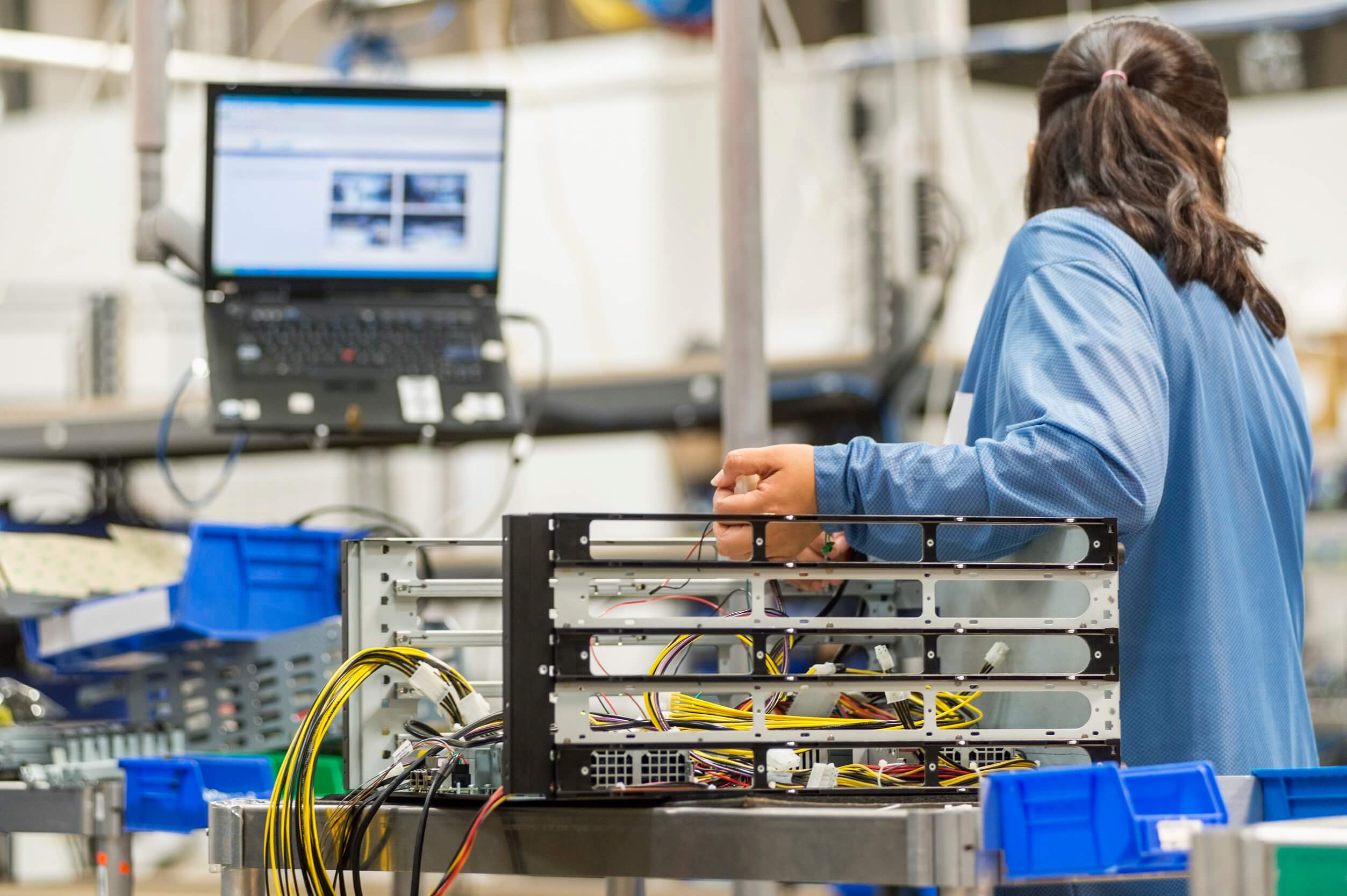

HYNAYT Group Project

A leading enterprise project in the electronics industry