Quick browsing

Unified Data Integrated Information Collaborative Business

Industry pain points

Frequent changes in plans

Demand plans fluctuate often, making it difficult to formulate rolling plans. Production scheduling is disrupted, order progress is opaque, and material flow is hard to control. Procurement cycles are long and forecasts are inaccurate.

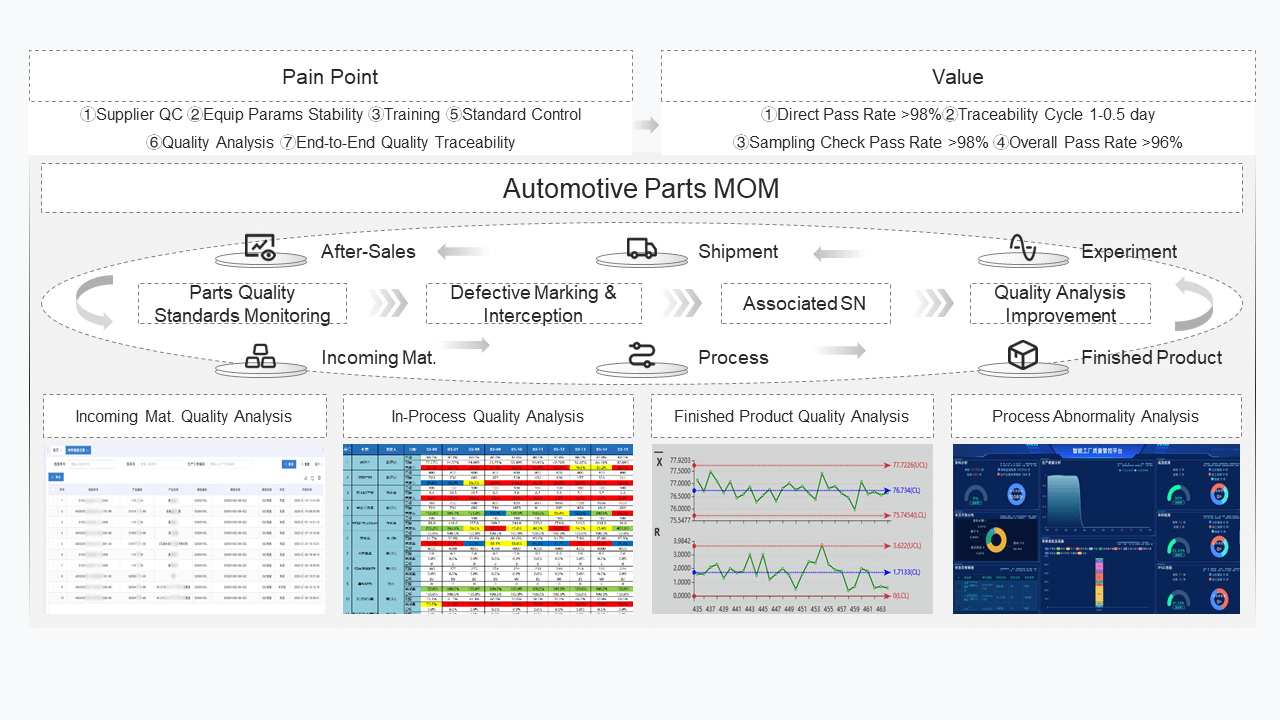

Difficulties in tracing quality issues

With numerous product models and diverse quality standards, manual records are cumbersome to analyze. The production process lacks transparency, resulting in low first-pass yield rates. Implementing comprehensive quality management is challenging, and APQP control is difficult to execute.

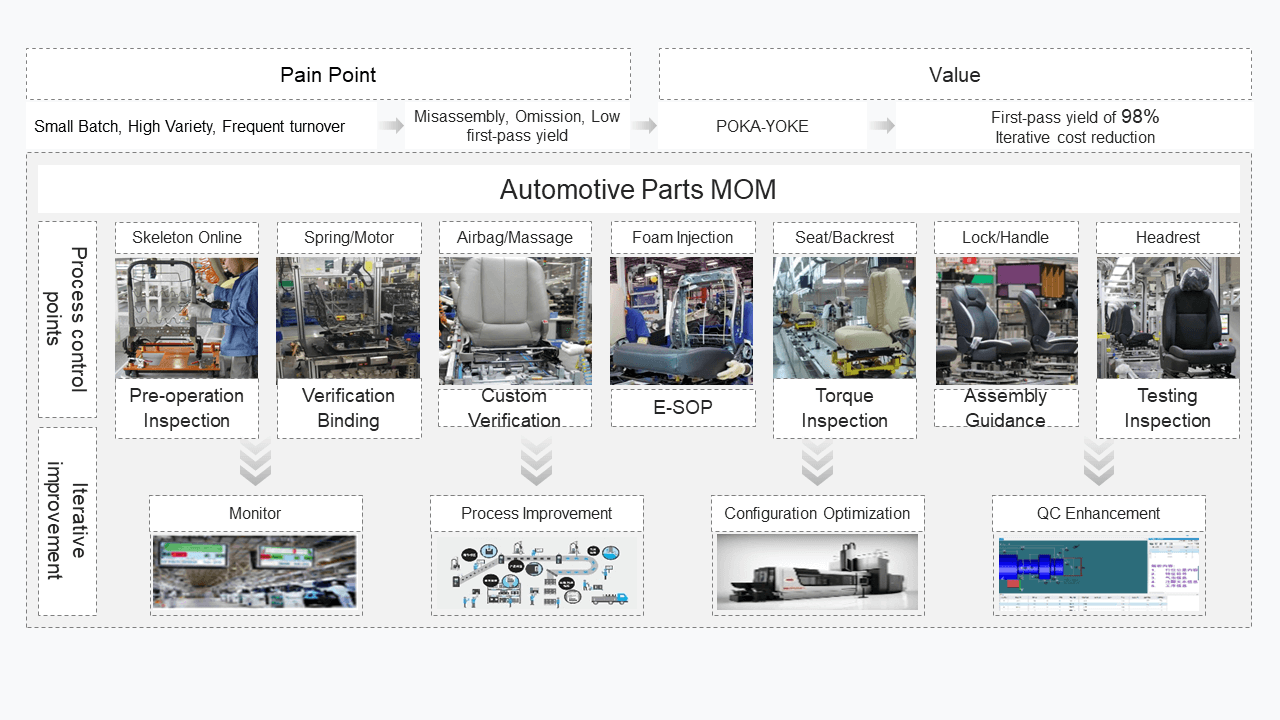

Errors and omissions in assembly

The fast production pace leads to issues such as mislabeled tags, incorrectly assembled parts, torque non-compliance, cosmetic defects, quantity shortages, and wrong material distribution.

Small Batch, High Variety

Product updates are rapid, customer delivery deadlines are tight, production scheduling is challenging, inserting new orders or changing production runs slowly, and there is a high level of material obsolescence.

Difficulties in Cost Optimization

Optimizing inventory costs is challenging, third-party inventory is hard to clarify, order-level costs are difficult to calculate, quality losses are hard to quantify, and energy consumption is tricky to allocate.

Revolution in the New Energy Industry

Transformation pressure is high as the industry shifts towards electrification, intelligence, lightweighting, high technology, and high quality. Operations management lacks clear metrics, and decision support is not agile.

Application scenarios

Production Planning

Pull-based Task Scheduling Enhances Collaboration Efficiency with Main Manufacturers

Production Execution

Online Control and Early Warning for Manufacturing Processes to Ensure Error-proofing, Foolproofing, and Leak-proofing in Production Operations

Warehouse & Logistics

Global Inventory Visibility and Dynamic Strategy Configuration Improve Logistics Operation Efficiency

Quality Control

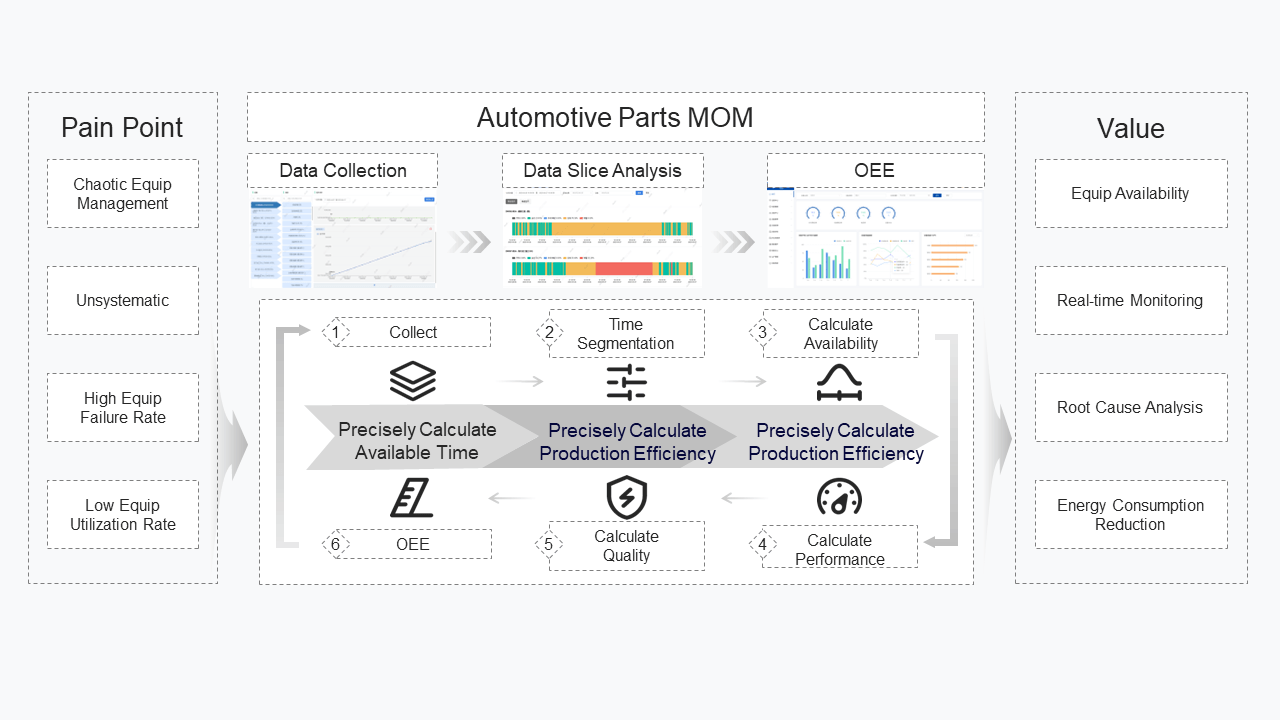

Equipment Maintenance

Respond to Equipment Failures and Abnormalities, Analyze and Provide Early Warning, and Conduct Precise OEE Analysis through Equipment Time Slicing

Implementation cases

Sanco Intelligent Connecting Technology Co.,Ltd. (Connectors)

Automotive interior company (Car seats)