Quick browsing

Unified Data Integrated Information Collaborative Business

Competitive advantages

Energy Management

Implement energy measurement improvements, detailing them down to the equipment/production line level. Collect energy data in millisecond intervals, establish data channels with business systems, develop optimized data analysis models, deeply explore the data, and aid decision-making.

Decision Analysis

Perform real-time data analysis, utilize powerful data penetration to trace back to the source, identify bottlenecks, address pain points, and enhance management efficiency.

Intelligent AGV Handling

AGV(Automated Guided Vehicles) can realize automated material handling, storage, and operation processes, improving the efficiency and effectiveness of logistics operations and achieving a labor-saving approach to internal plant logistics.

E-SOP

From research and development to production, online collaboration is enabled through dynamic electronic standard operating procedures, achieving a comprehensive paperless work environment in the workshop.

Andon

The Andon system integrates abnormal alerts from equipment, production, and management on the production line, notifying multiple terminals such as PCs, mobile phones, and wearable devices in real-time. This facilitates prompt response and timely handling by personnel.

LIMS(Laboratory Management)

Centered on the ISO/IEC17025 laboratory standards, LIMS builds a one-stop platform for testing services, realizing digital management of the testing process.

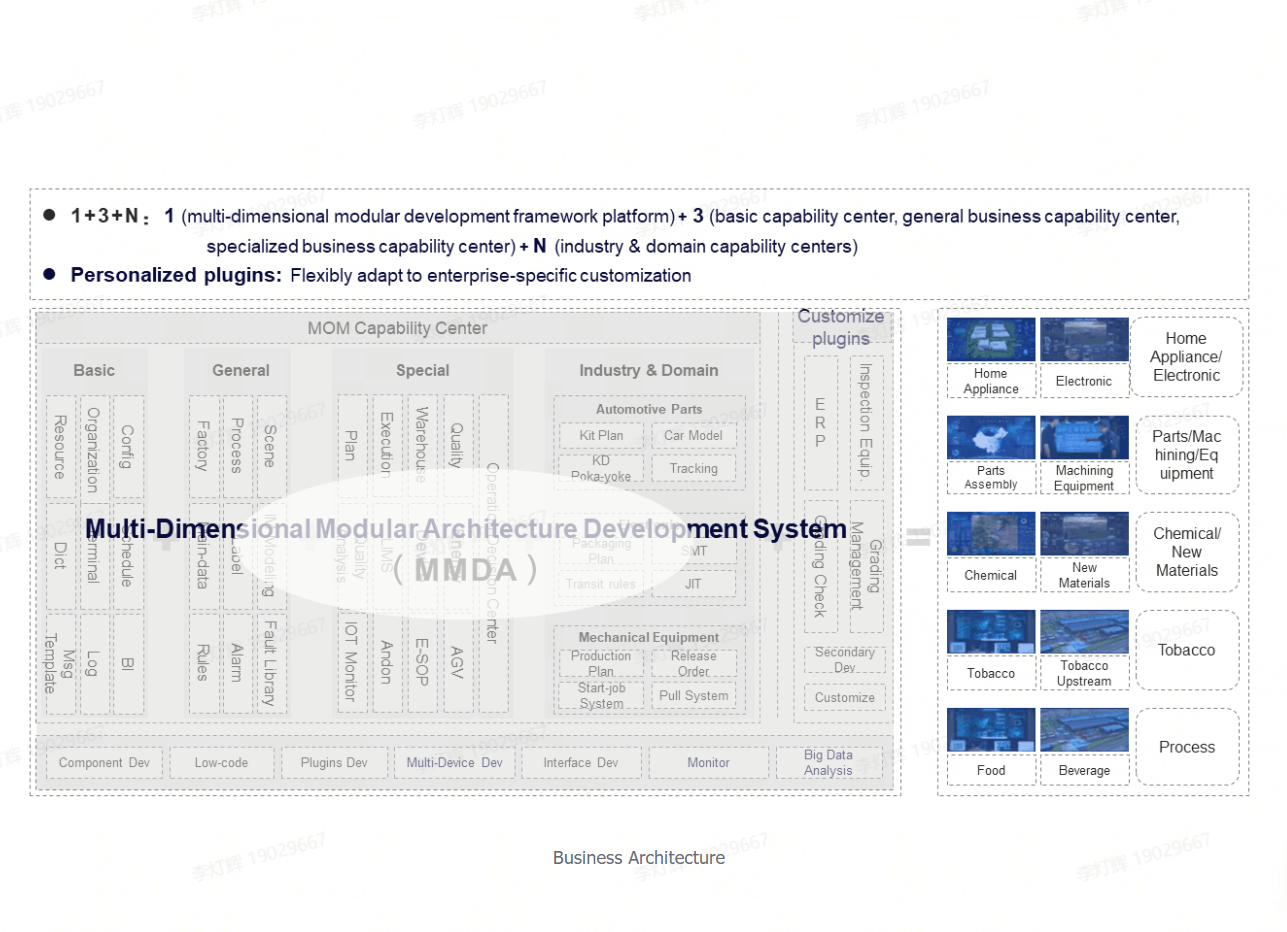

Platform architecture

1+3+N

Personalized plugins

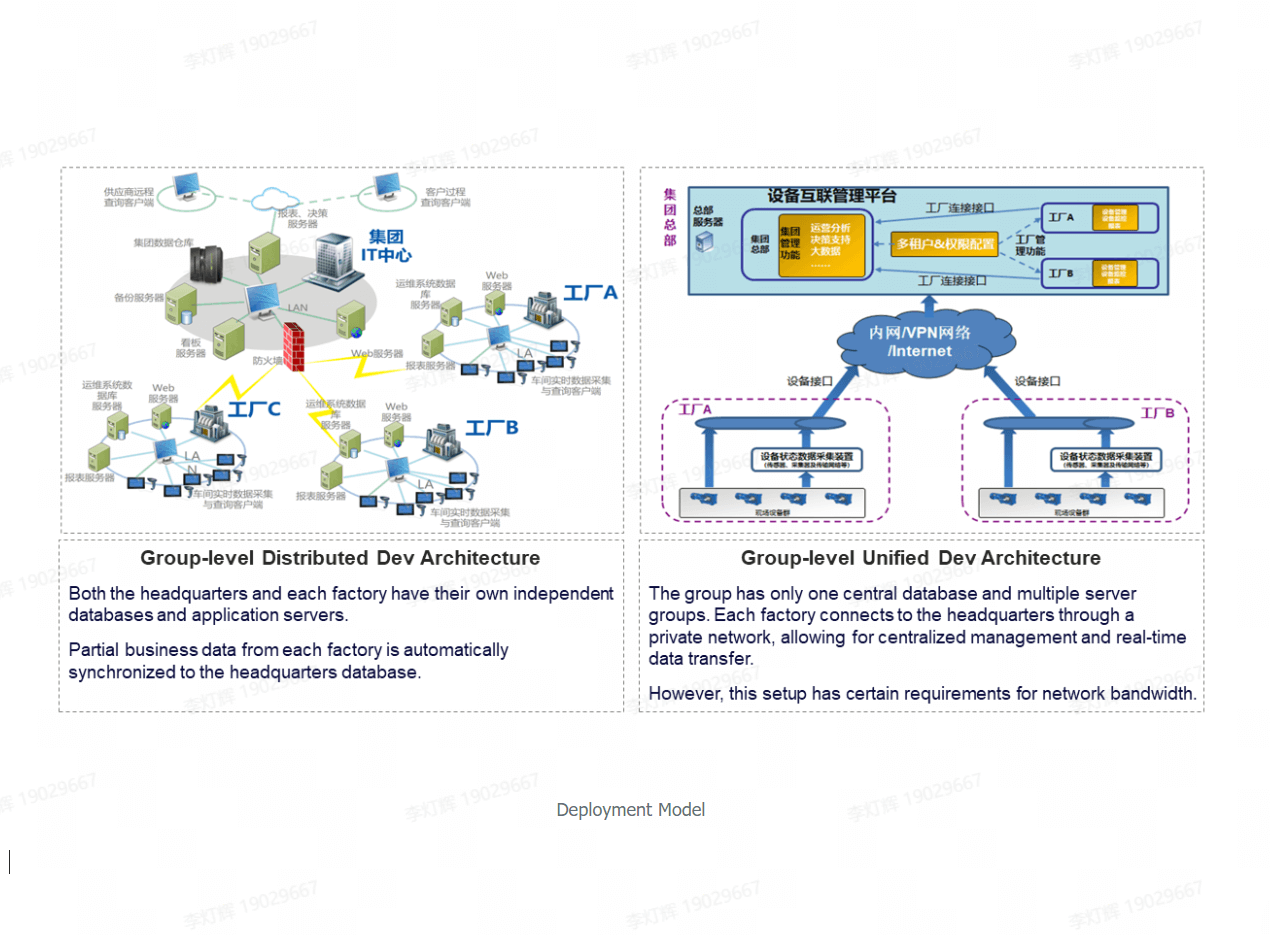

Distributed Dev Architecture

Unified Dev Architecture

Application scenarios

Production Planning

Build a demand-driven dashboard integrated with customer business to enable global planning and scheduling. Leverage the real-time material requirement analysis and shortage alert based on the kit model, making it easy to handle last-minute orders.

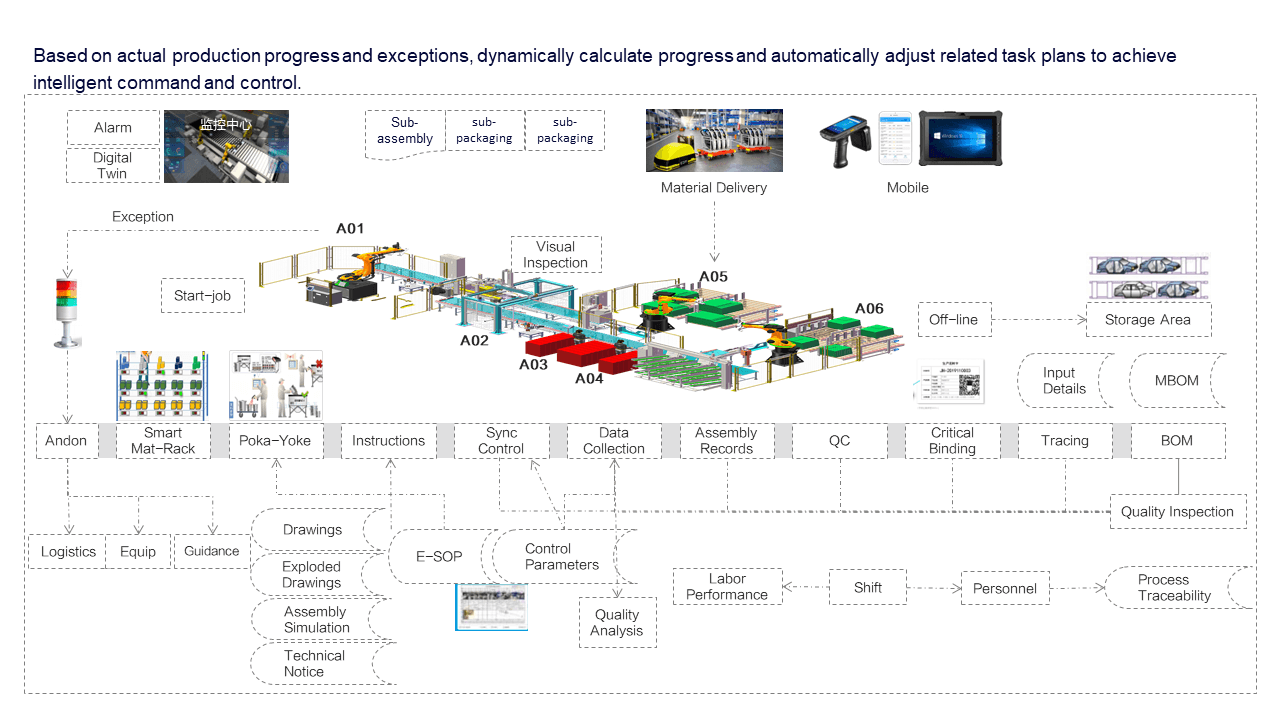

Production Execution

Based on actual production progress and exceptions, dynamically calculate progress and automatically adjust related task plans to achieve intelligent command and control.

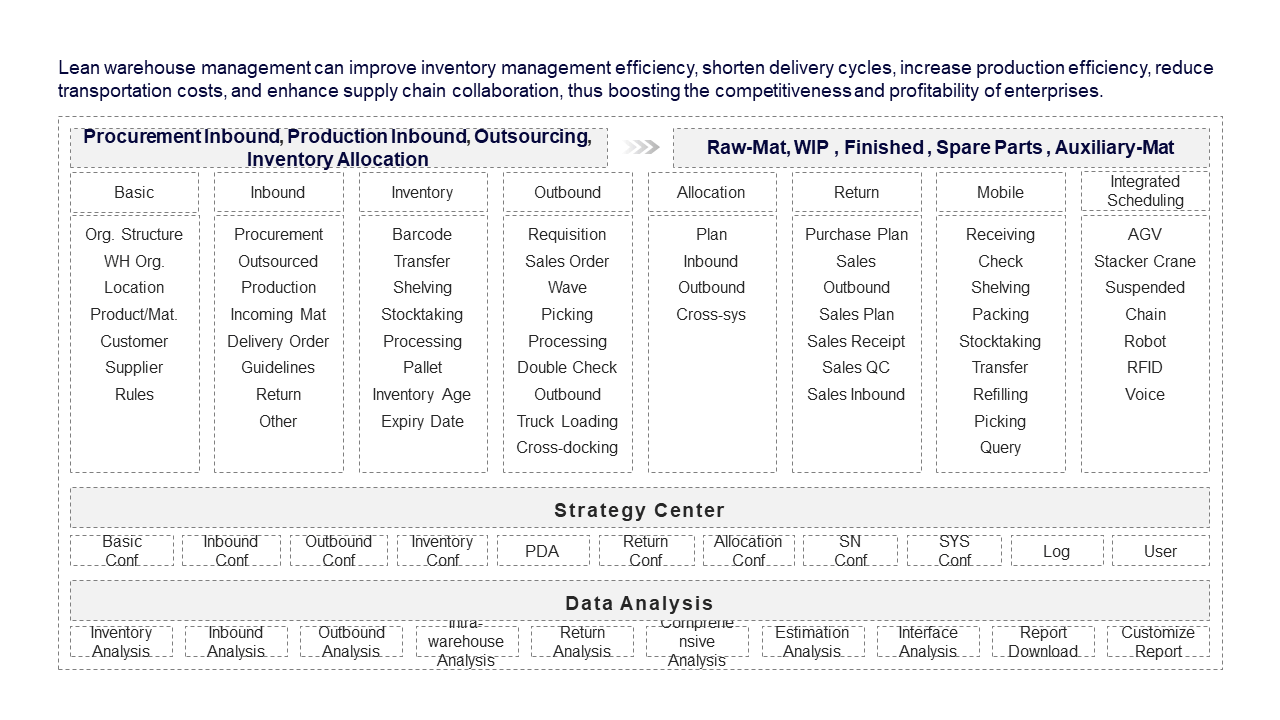

Warehouse & Logistics

Lean warehouse management can improve inventory management efficiency, shorten delivery cycles, increase production efficiency, reduce transportation costs, and enhance supply chain collaboration, thus boosting the competitiveness and profitability of enterprises.

Quality Control

Establishing a comprehensive quality management system that encompasses IQC to OQC;

Implementing graphical and visual real-time monitoring of key quality indicators, and establishing product quality archives.

Equipment Maintenance

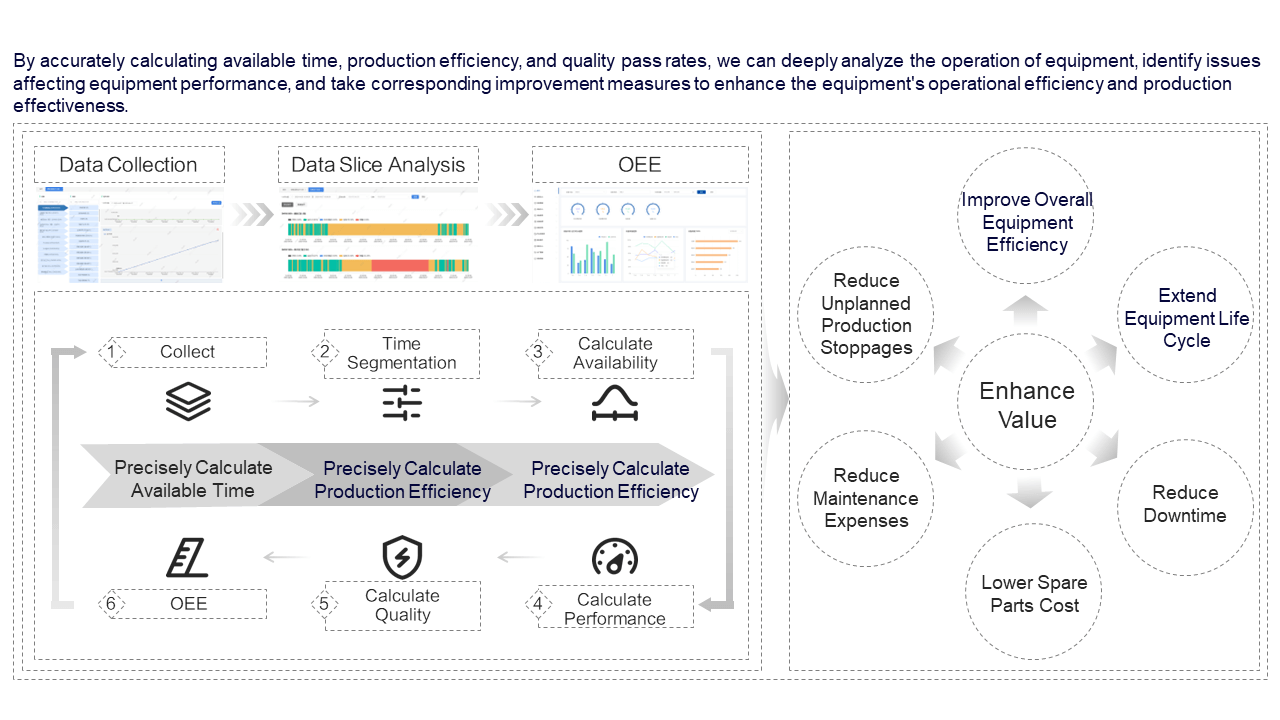

By accurately calculating available time, production efficiency, and quality pass rates, we can deeply analyze the operation of equipment, identify issues affecting equipment performance, and take corresponding improvement measures to enhance the equipment's operational efficiency and production effectiveness.

Implementation cases

Sanco Intelligent Connecting Technology Co.,Ltd. (Connectors)

Automotive interior company (Car seats)

Chemical new material company